The essential tech needed to protect oil platforms, workers, and the environment

Oil platforms operate in one of the most high-risk environments where security and environmental risks are ever-present. To mitigate these risks, cutting-edge security technologies such as thermal imaging, explosion-proof devices, and AI-driven algorithms now play a pivotal role in protecting oil platforms and workers, and minimizing the impact on the environment.

Despite the shift to green energy, the world remains heavily dependent on oil and gas and the platforms that extract them from the ground. Protecting these valuable assets—and the people who work on them—is a growing business. According to Grand View Research, the global oil and gas security market was valued at USD 25.51 billion in 2023 and is expected to grow at a 5.4% CAGR from 2024 to 2030. For security integrators, this trend clearly presents a major opportunity. However, with increasing market size comes a heightened complexity of threats, making it vital for security providers to deliver integrated, state-of-the-art solutions.

Key challenges in safeguarding offshore oil platforms

The volatile nature of hydrocarbons means that oil rigs are particularly at risk of fire and explosions. Ensuring the health and safety of employees in such an environment is a constant challenge, necessitating strict safety protocols and real-time monitoring to mitigate potential hazards.

Moreover, offshore platforms are exposed to extreme weather conditions—salty sea air, high winds, and low visibility caused by fog and rain. These can quickly degrade traditional security equipment which, in turn, can lead to operational downtime and gaps in monitoring.

With hydrocarbon products being high-value targets, offshore platforms are also vulnerable to theft, piracy, and even terrorist attacks. Perimeter security must be top-of-mind to protect both personnel and assets.

What’s more, in addition to protecting the platforms and those who work on them, oil companies are under increasing pressure to protect the environment. Implementing eco-friendly security technologies that minimize the impact on local ecosystems is now a critical responsibility for those who operate oil platforms.

Essential technologies to address oil platform challenges

To overcome these significant challenges, oil and gas companies need to adopt integrated security systems and incorporate modern technologies such as thermal imaging, explosion-proof devices, and deep-learning algorithms. These work together to assist in protecting assets and workers, as well as helping meet environmental regulations. Together, such technologies safeguard platforms and reduce operational downtime, which, in turn, saves costs and optimizes profitability.

- Explosion-proof cameras: essential for high-risk environments

Explosion-proof cameras are usually built with stainless-steel casings to prevent sparks or heat from interacting with flammable gases. Designed to meet international anti-corrosion standards, these cameras offer durability in salty and humid maritime conditions. Their robust design is crucial for maintaining safety in high-risk oil and gas environments, minimizing the chances of fires or explosions.

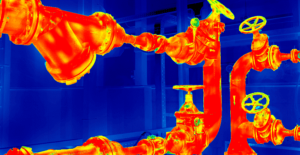

- Thermal imaging: early detection of equipment failures and hazards

Thermal imaging is essential for early detection of equipment overheating, fires, and gas leaks—critical factors in reducing the risk of accidents on oil platforms. Thermal cameras can detect subtle changes in temperature, enabling operators to respond swiftly to potential hazards before they escalate into more serious issues.

- Deep-learning algorithms: improving threat detection by reducing false alarms

On-board deep-learning algorithms ensure that cameras generate alerts immediately for certain types of incidents. These algorithms are able to separate false alarms (such as those caused by moving objects such as seabirds, high waves, or storms), from genuine threats such as people invading the platform perimeter. This allows security teams to focus on real incidents, improving response times and overall platform safety.

Integrated solutions: how these technologies work at La Santa Maria oil drilling platform

A real-world example of how technologies such as these are working together can be found on the La Santa Maria oil drilling platform in the Gulf of Mexico. Here, LATINA Construction and Drilling, a leading geothermal drilling company, partnered with the system integrator STC Global System to deploy Hikvision’s advanced security solutions on their platform.

The installation included Thermal & Optical Bi-spectrum Network Bullet Cameras(DS-2TD2637-35/QY) and Explosion-Proof Thermographic Network Bullet Cameras (DS-2DB4236I-CWX). Hikvision explosion-proof cameras, housed in 316L stainless casings, significantly enhance worker safety by minimizing the risk of camera-related sparks. Additionally, the cameras’ thermal imaging capabilities allow for early detection of temperature anomalies, ensuring swift responses to potential fires or equipment malfunctions, while adhering to environmental regulations.

Furthermore, the deep-learning algorithms have proven invaluable by minimizing false alarms, allowing the platform’s security team to focus solely on real threats. Automated alerts for perimeter breaches, such as unauthorized personnel entering restricted areas, ensure that potential security risks are addressed in real time. Corrosion-resistant cameras, meanwhile, offer a high degree of chemical resistance, making them ideal for the harsh maritime conditions of the Gulf of Mexico. This reliability translates into fewer repairs and lower maintenance costs over time, delivering long-term value to LATINA Construction and Drilling.

For more information, please visit us at www.hikvisionindia.com